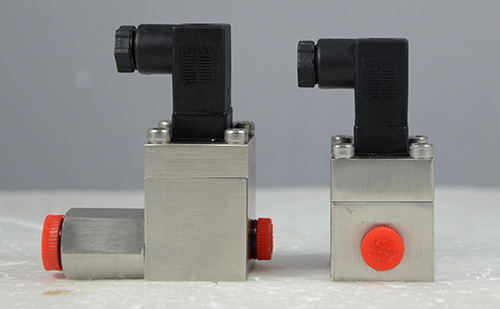

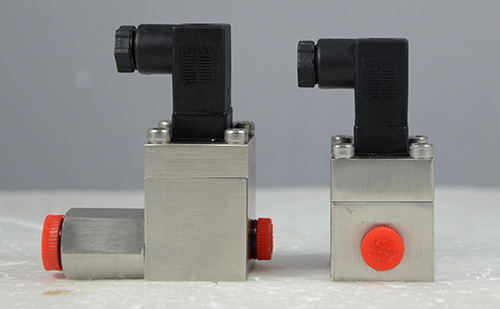

additive injection mini flowmeter

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is specializedin super micro flow meter,oval gear flow meter ,coriolis mass flowmeter,electromagnetic flow meter,piston flow meter,spur gear flow meter,gearpump,gear metering pump design and R&D. After more than 10 years ofdevelopment, a full-scale flow metering equipment has been formed. JSN has been widely used in the world. Especially in the fields ofchemical fiber, spinning, chemical industry, polyurethane, and dispensing, theautomation requirements for flow meter and gear pump are improved and relied onwork basis,Performance,Equipment structure Development, control technologies,etc. have carried out many researches and achieved certain results.

additive injection mini flowmeter

Onceupon a time, China"s manufacturing industry in the world"s processing plant hasalways been the "low quality" representative of the world. Inparticular, the Oval gear flow meter for automatic process control has theadvantages of large volume, large noise, small turndown ratio, , The use ofeasy to leak, instability and so on, leaving customers a headache is that manyproblems in the early stages of product does not appear, and in the event ofafter-sale is very troublesome, bothering money, these are domestic objectiveobjective existence of Oval gear flow meter Therefore, users buy Oval gear flowmeter is like buying lottery tickets, do not know sent to the installation siteOval gear flow meter is a blessing, in a sense, is a matter of course, whilethe base depth meter appeared to solve these problems in one fell swoop.

Base deep gear wheel flowmeter on the production of all caliberflowmeters, basically have stock inventory, which in itself shows that thecompany"s funds and sales are good, we dare to do inventory. Hee Oval gear flowmeter has two national inventions, In the process of production qualitycontrol, starting from the beginning of the procurement of raw materials, everyproduction and precision machining links careful examination, each of the Ovalgear flow meter factory must be continuous calibration test. Processinstallation ISO9001 quality management system strictly enforced, the producthas the CE, SGS and other EU certification. Our company has "the qualityof Germany, China"s manufacturing" as the slogan to create a world-classoval gear flow, real automation instrumentation industry Benchmarking business.

additive injection mini flowmeter

The Ovalgear flow meter is composed of a flow transmitter and a counting mechanism. Themain part of the transmitter consists of a measuring chamber equipped with apair of gear rotors and a sealing coupling. The counting mechanism consists ofa speed reducing mechanism, a precision adjusting mechanism, a counter and apower Pulse transmitter and other components.

additive injection mini flowmeter

Item | model | K-factor | The minimum flow | Flow range | Connection size |

Gear flow meter | CX-G0.025-P-AL | 0.025ml | 0.001L/Min | 0.004~1 L/min | G1/8 |

gear flow meter | CX-G0.025-P-SS | 0.025ml | 0.001L/Min | 0.004~1 L/min | G1/8 |

gear flow meter | CX-G0.04-P-AL | 0.04ml | 0.004L/min | 0.01~2L/min | G1/4 |

gear flow meter | CX-G0.04-P-SS | 0.04ml | 0.004L/min | 0.01~2L/min | G1/4 |

gear flow meter | CX-G0.1-P-AL | 0.1ml | 0.008L/min | 0.02~4L/min | G3/8 |

gear flow meter | CX-G0.1-P-SS | 0.1ml | 0.008L/min | 0.02~4L/min | G3/8 |

gear flow meter | CX-G0.2-P-AL | 0.245ml | 0.01L/Min | 0.08~8L/min | G3/8 |

gear flow meter | CX-G0.2-P-SS | 0.245ml | 0.01L/Min | 0.08~8L/min | G3/8 |

gear flow meter | CX-G0.4-P-AL | 0.4ml | 0.01L/Min | 0.1~20L/min | G1/2 |

gear flow meter | CX-G0.4-P-SS | 0.4ml | 0.01L/Min | 0.1~20L/min | G1/2 |

gear flow meter | CX-G1-P-AL | 1ml | 0.02L/Min | 0.2~40L/min | G1/2 |

gear flow meter | CX-G1-P-SS | 1ml | 0.02L/Min | 0.2~40L/min | G1/2 |

gear flow meter | CX-G2-P-AL | 2ml | 0.04L/Min | 0.5-60L/min | G3/4 |

gear flow meter | CX-G2-P-SS | 2ml | 0.04L/Min | 0.5-60L/min | G3/4 |

Remark: Hightemperature, high pressure, high frequency, special connection, specialmaterials, two-way measurement, etc. can be customized

Commonfault causes, troubleshooting

a. Thegear does not rotate: The gear is jammed by debris, the gear and cavity need tobe cleaned, and the filter is cleaned or replaced.

b. Thesmall flow error is too large: The flowmeter is installed in the wrongdirection, the best position goes up and down, or there are impurities to blockthe gear and need to be cleaned.

c. Theflow error is too large: The actual use flow range is less than or far greaterthan the flowmeter range. The corresponding flowmeter must be selected.

d. Noflow sensor signal: The gear is stuck or the circuit is connected incorrectlyor the circuit is damaged. The gear and cavity must be cleaned, or the circuitmust be correctly connected or replaced.